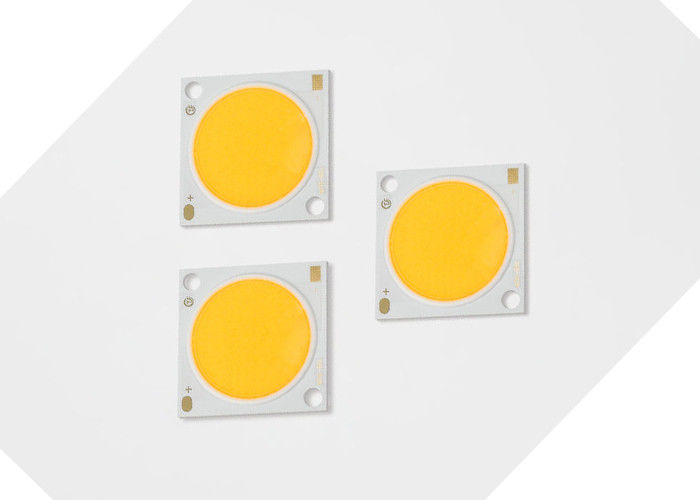

100W COB 120W LED CHIPS CLU058 bridlgeux 80w super high lumen 160lm/w Chips LED COB LM80 5 years warranty

Features Of Cob LED

1. Good thermal performance and wide hot channel.

2. The spot is uniform.

3. Energy saving and environmental protection, high light efficiency.

4. High brightness, low light decay, polished.

5. Easy to use and easy to install.

6. Strong antistatic ability.

|

Part Number

|

Typical Power (W) |

Nominal CCT (K) |

CRI

|

Minimum Pulsed Flux (lm) |

Typical Pulsed Flux (lm) |

Typical Voltage (V) |

Nominal Current (mA) |

Typical Efficacy (lm/W) |

| CL54351825P430E*7 |

115.2 |

3000 K |

70 |

12336 |

13264 |

51.2 |

2250 |

160 |

| CL54351825P435E*7 |

115.2 |

3500 K |

70 |

12490 |

13430 |

51.2 |

2250 |

162 |

| CL54351825P440E*7 |

115.2 |

4000 K |

70 |

12567 |

13513 |

51.2 |

2250 |

163 |

| CL54351825P450E*7 |

115.2 |

5000 K |

70 |

12721 |

13679 |

51.2 |

2250 |

165 |

| CL54351825P457E*7 |

115.2 |

5700 K |

70 |

12798 |

13761 |

51.2 |

2250 |

166 |

| CL54351825P465E*7 |

115.2 |

6500 K |

70 |

12721 |

13679 |

51.2 |

2250 |

165 |

| CL54351825P422E*8 |

115.2 |

2200 K |

80 |

10485 |

11274 |

51.2 |

2250 |

136 |

| CL54351825P427E*8 |

115.2 |

2700 K |

80 |

11256 |

12103 |

51.2 |

2250 |

146 |

| CL54351825P430E*8 |

115.2 |

3000 K |

80 |

11565 |

12435 |

51.2 |

2250 |

150 |

| CL54351825P435E*8 |

115.2 |

3500 K |

80 |

11719 |

12601 |

51.2 |

2250 |

152 |

| CL54351825P440E*8 |

115.2 |

4000 K |

80 |

11950 |

12850 |

51.2 |

2250 |

155 |

| CL54351825P450E*8 |

115.2 |

5000 K |

80 |

12027 |

12932 |

51.2 |

2250 |

156 |

| CL54351825P457E*8 |

115.2 |

5700 K |

80 |

12181 |

13098 |

51.2 |

2250 |

158 |

| CL54351825P465E*8 |

115.2 |

6500 K |

80 |

12027 |

12932 |

51.2 |

2250 |

156 |

| CL54351825P422E*9 |

115.2 |

2200 K |

90 |

9329 |

10031 |

51.2 |

2250 |

121 |

| CL54351825P427E*9 |

115.2 |

2700 K |

90 |

10100 |

10860 |

51.2 |

2250 |

131 |

| CL54351825P430E*9 |

115.2 |

3000 K |

90 |

10408 |

11192 |

51.2 |

2250 |

135 |

| CL54351825P435E*9 |

115.2 |

3500 K |

90 |

10562 |

11357 |

51.2 |

2250 |

137 |

| CL54351825P440E*9 |

115.2 |

4000 K |

90 |

10639 |

11440 |

51.2 |

2250 |

138 |

| CL54351825P450E*9 |

115.2 |

5000 K |

90 |

10794 |

11606 |

51.2 |

2250 |

140 |

| CL54351825P457E*9 |

115.2 |

5700 K |

90 |

10871 |

11689 |

51.2 |

2250 |

141 |

Competitive advantages:

TYF is a market-leading innovator in highly integrated and ultra-high power flip-chip LEDs.

1. Strong R&D force

* A strong R&D team composed of more than 40 experienced engineers.

* CNAS accredited laboratory.

* Seasonal launch of highly competitive new products.

* Revolutionary launch of a full range of high-power, highly integrated ceramic flip-chip LEDs.

5.1 Color Binning Information

Figure 1: Graph of Test Bins in xy Color Space (Pulsed Test Conditions, Tj = 25°C)

CIE1931-x

Table 38: 2-Step to 5-step MacAdam ellipse color bin definitions for TYF CoB Core Range

|

Nominal

CCT

|

Center Point |

MAJOR AXIS (a , b) |

Ellipse

Rotation Angel,θ

|

| X |

Y |

2-Step |

3-Step |

5-Step |

| 2200K |

0.5018 |

0.4153 |

(0.0048 , 0.0027) |

(0.0072, 0.0041) |

(0.0120, 0.0067) |

39.9 |

| 2500K |

0.4806 |

0.4141 |

(0.0050, 0.0027) |

(0.0076, 0.0041) |

(0.0126, 0.0068) |

53.1 |

| 2700K |

0.4575 |

0.4101 |

(0.0053, 0.0027) |

(0.0080, 0.0041) |

(0.0133, 0.0068) |

54.1 |

| 3000K |

0.4338 |

0.4030 |

(0.0057, 0.0028) |

(0.0086, 0.0042) |

(0.0142, 0.0069) |

53.7 |

| 3500K |

0.4073 |

0.3917 |

(0.0062, 0.0028) |

(0.0093, 0.0041) |

(0.0155, 0.0069) |

54.0 |

| 4000K |

0.3818 |

0.3797 |

(0.0063, 0.0027) |

(0.0093, 0.0042) |

(0.0157, 0.0068) |

53.4 |

| 5000K |

0.3447 |

0.3553 |

(0.0054, 0.0024) |

(0.0081, 0.0035) |

(0.0135, 0.0059) |

59.8 |

| 5700K |

0.3290 |

0.3417 |

(0.0048, 0.0021) |

(0.0072, 0.0032) |

(0.0119, 0.0052) |

58.8 |

| 6500K |

0.3123 |

0.3282 |

(0.0044, 0.0018) |

(0.0066, 0.0027) |

(0.0110, 0.0045) |

58.1 |

6.1 Table 39: Maximum Ratings

Notes for Table 39:

- Driven the arrays at higher currents however lumen maintenance may be reduced.

- Proper current derating must be observed to maintain junction temperature below the maximum

- Pulsed operation with a peak drive current equal to the stated peak pulsed forward current is acceptable if the pulse on-time is ≤1ms per cycle and the duty cycle is ≤10%

- Light emitting diodes are not designed to be driven in reverse voltage and will not produce light under this condition. Maximum rating provided for reference only.

Notes: 1. All dimension tolerance is ±0.2mm unless otherwise noted. 2. Tc measurement point at cathode

RECOMMENDED SOLDERING CONDITION

For manual soldering. Please use lead-free soldering and the soldering shall be implemented using a soldering bit at a

temperature lower than 350C, and shall be finished within 3.5 seconds for one land. No external force shall be applied

to resin part while soldering is implemented. Next process of soldering should be carried out after the product has

return to ambient temperature. CAUTION: TEMPERATURE CONTROL

Product Packing and Labeling

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!