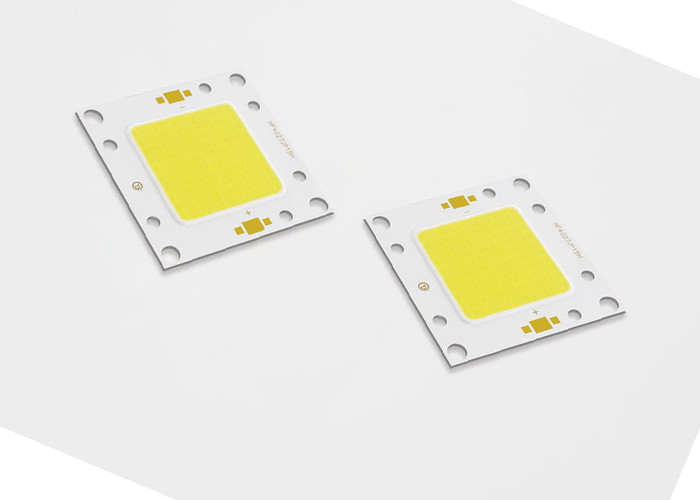

3-200W High Power Cob LED Copper Base Material Track Spot Light Lighting

2 Advantages

• High stability for outdoor application

• Significantly reduced thermal resistance and

increased operating temperature

• Uniform, consistent white light • Lower operating cost • Easy to use with daylight and motion detectors to

enable increased energy saving

• Reduced maintenance cost • Environmentally friendly, no disposal issue

The part number designation for TYF Special Series LED arrays is explained as follows:

|

Part Number

|

Typical Power (W) |

Nominal CCT (K) |

CRI

|

Minimum Pulsed Flux (lm) |

Typical Pulsed Flux (lm) |

Typical Voltage (V) |

Nominal Current (mA) |

Typical Efficacy (lm/W) |

| CL54351818P430E*7 |

82.9 |

3000 K |

70 |

12027 |

12932 |

51.2 |

1620 |

156 |

| CL54351818P435E*7 |

82.9 |

3500 K |

70 |

12181 |

13098 |

51.2 |

1620 |

158 |

| CL54351818P440E*7 |

82.9 |

4000 K |

70 |

12258 |

13181 |

51.2 |

1620 |

159 |

| CL54351818P450E*7 |

82.9 |

5000 K |

70 |

12413 |

13347 |

51.2 |

1620 |

161 |

| CL54351818P457E*7 |

82.9 |

5700 K |

70 |

12490 |

13430 |

51.2 |

1620 |

162 |

| CL54351818P465E*7 |

82.9 |

6500 K |

70 |

12413 |

13347 |

51.2 |

1620 |

161 |

| CL54351818P422E*8 |

82.9 |

2200 K |

80 |

10100 |

10860 |

51.2 |

1620 |

131 |

| CL54351818P427E*8 |

82.9 |

2700 K |

80 |

10948 |

11772 |

51.2 |

1620 |

142 |

| CL54351818P430E*8 |

82.9 |

3000 K |

80 |

11256 |

12103 |

51.2 |

1620 |

146 |

| CL54351818P435E*8 |

82.9 |

3500 K |

80 |

11410 |

12269 |

51.2 |

1620 |

148 |

| CL54351818P440E*8 |

82.9 |

4000 K |

80 |

11487 |

12352 |

51.2 |

1620 |

149 |

| CL54351818P450E*8 |

82.9 |

5000 K |

80 |

11642 |

12518 |

51.2 |

1620 |

151 |

| CL54351818P457E*8 |

82.9 |

5700 K |

80 |

11796 |

12684 |

51.2 |

1620 |

153 |

| CL54351818P465E*8 |

82.9 |

6500 K |

80 |

11642 |

12518 |

51.2 |

1620 |

151 |

| CL54351818P422E*9 |

82.9 |

2200 K |

90 |

8943 |

9616 |

51.2 |

1620 |

116 |

| CL54351818P427E*9 |

82.9 |

2700 K |

90 |

9791 |

10528 |

51.2 |

1620 |

127 |

| CL54351818P430E*9 |

82.9 |

3000 K |

90 |

10023 |

10777 |

51.2 |

1620 |

130 |

| CL54351818P435E*9 |

82.9 |

3500 K |

90 |

10177 |

10943 |

51.2 |

1620 |

132 |

| CL54351818P440E*9 |

82.9 |

4000 K |

90 |

10254 |

11026 |

51.2 |

1620 |

133 |

| CL54351818P450E*9 |

82.9 |

5000 K |

90 |

10408 |

11192 |

51.2 |

1620 |

135 |

| CL54351818P457E*9 |

82.9 |

5700 K |

90 |

10485 |

11275 |

51.2 |

1620 |

136 |

5.1 Color Binning Information

Figure 1: Graph of Test Bins in xy Color Space (Pulsed Test Conditions, Tj = 25°C)

CIE1931-x

Table 38: 2-Step to 5-step MacAdam ellipse color bin definitions for TYF CoB Core Range

|

Nominal

CCT

|

Center Point |

MAJOR AXIS (a , b) |

Ellipse

Rotation Angel,θ

|

| X |

Y |

2-Step |

3-Step |

5-Step |

| 2200K |

0.5018 |

0.4153 |

(0.0048 , 0.0027) |

(0.0072, 0.0041) |

(0.0120, 0.0067) |

39.9 |

| 2500K |

0.4806 |

0.4141 |

(0.0050, 0.0027) |

(0.0076, 0.0041) |

(0.0126, 0.0068) |

53.1 |

| 2700K |

0.4575 |

0.4101 |

(0.0053, 0.0027) |

(0.0080, 0.0041) |

(0.0133, 0.0068) |

54.1 |

| 3000K |

0.4338 |

0.4030 |

(0.0057, 0.0028) |

(0.0086, 0.0042) |

(0.0142, 0.0069) |

53.7 |

| 3500K |

0.4073 |

0.3917 |

(0.0062, 0.0028) |

(0.0093, 0.0041) |

(0.0155, 0.0069) |

54.0 |

| 4000K |

0.3818 |

0.3797 |

(0.0063, 0.0027) |

(0.0093, 0.0042) |

(0.0157, 0.0068) |

53.4 |

| 5000K |

0.3447 |

0.3553 |

(0.0054, 0.0024) |

(0.0081, 0.0035) |

(0.0135, 0.0059) |

59.8 |

| 5700K |

0.3290 |

0.3417 |

(0.0048, 0.0021) |

(0.0072, 0.0032) |

(0.0119, 0.0052) |

58.8 |

| 6500K |

0.3123 |

0.3282 |

(0.0044, 0.0018) |

(0.0066, 0.0027) |

(0.0110, 0.0045) |

58.1 |

Notes for Table 12:

- Driven the arrays at higher currents however lumen maintenance may be reduced.

- Proper current derating must be observed to maintain junction temperature below the maximum

- Pulsed operation with a peak drive current equal to the stated peak pulsed forward current is acceptable if the pulse on-time is ≤1ms per cycle and the duty cycle is ≤10%

- Light emitting diodes are not designed to be driven in reverse voltage and will not produce light under this condition. Maximum rating provided for reference only.

Notes: 1. All dimension tolerance is ±0.2mm unless otherwise noted. 2. Tc measurement point at cathode

RECOMMENDED SOLDERING CONDITION

For manual soldering. Please use lead-free soldering and the soldering shall be implemented using a soldering bit at a

temperature lower than 350C, and shall be finished within 3.5 seconds for one land. No external force shall be applied

to resin part while soldering is implemented. Next process of soldering should be carried out after the product has

return to ambient temperature. CAUTION: TEMPERATURE CONTROL

Our Services:

1. Your inquiry can be replied within 24 working hours;

2. Well-trained and experienced staff to answer all your questions in fluent English;

3. OEM&ODM, we can help you design and put into products;

4. Protect your sales area, design concept and all your private information.

Q1. How to get the product?

Please kindly send enquiry to me, I'll be your guide.

Q2. If your company can custom product as my required and put my logo on?

All of our product are designed and customized as required including color, print, pattern and logo.

Q3. How about the warranty?

Normally we offer 24 months warranty, depends on products, some products have 12 months warranty.

Please contact me for more details.

Q4. How can I pay the order?

Usually we accept T/T, Western Union and PayPal. If you want to pay by other ways, Please contact me.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!